PEEK

PEEK is the abbreviation for polyetheretherketon, also referred to as polyetheretherketone. It

is a high quality technical synthetic substance. The material has unique qualities, as it can be

used at the highest temperature and it has a high level of chemical resistance. PEEK also has

high dimensional stability.

PEEK is a thermoplastic. Thermoplastics are synthetic materials that turn soft under high

temperatures. That is why polyetheretherketone is perfect for laser cutting. PEEK’s melting

point is around 340 °C. We process it very precisely. This gives it a nice, smooth surface. Are

you looking for a synthetic material that meets high qualitative standards? Then, PEEK plastic

is most likely for you.

The properties of PEEK allow it to be widely applicable and therefore very popular.

PEEK plastic

PEEK plastic is used in various industries. A number of examples are:

- Aerospace industry: as a replacement for metal, for example for hinges or pipes

- Medical industry: implants, surgical instruments that have to be sterilized multiple times

Oil and gas extraction: for example for pipes

We can also see the material used extensively in the automobile industry, electrical engineering, mechanical engineering, and in textile processing. And for example, in electrical isolation, pump housing and pipes in HPLC equipment (high-performance liquid chromatography). PEEK plastic can be very widely used.

Polyetheretherketone types

There are various types of polyetheretherketone that have been modified. This can amend or strengthen the characteristics of PEEK. Examples are:

- PEEK GF30: in which 30% of glass fibre has been added. This provides it with the highest mechanical stability in comparison to all the other types of PEEK.

- PEEK mod.: to which PTFE, carbon fibre and granite has been added. This makes it even more mechanically stable and even more resistant to wear and tear. PEEK mod. also has good sliding properties.

As you can tell, polyetheretherketone is very versatile. Do you want advice on which polyetheretherketone you should choose, then contact us.

Why PEEK?

- High resistance at high temperatures

- High resistance for wear and tear

- High resistance against radiation

- Strong, about 100 Mpa. Heavy mechanical resistance

Very pure (suitable for contact with foodstuffs) - Can be used at high temperatures. Consistent at 260 °C or to just over 300 °C.

- Chemically resistant to almost all substances, except sulphuric acid

- Dimensionally stable

- Tough

Questions regarding PEEK? Would you like to receive a price overview?

Would you like to request a quote? Or do you have a question regarding PEEK or a certain challenge? Contact us. We will contact you within 24 hours, guaranteed!

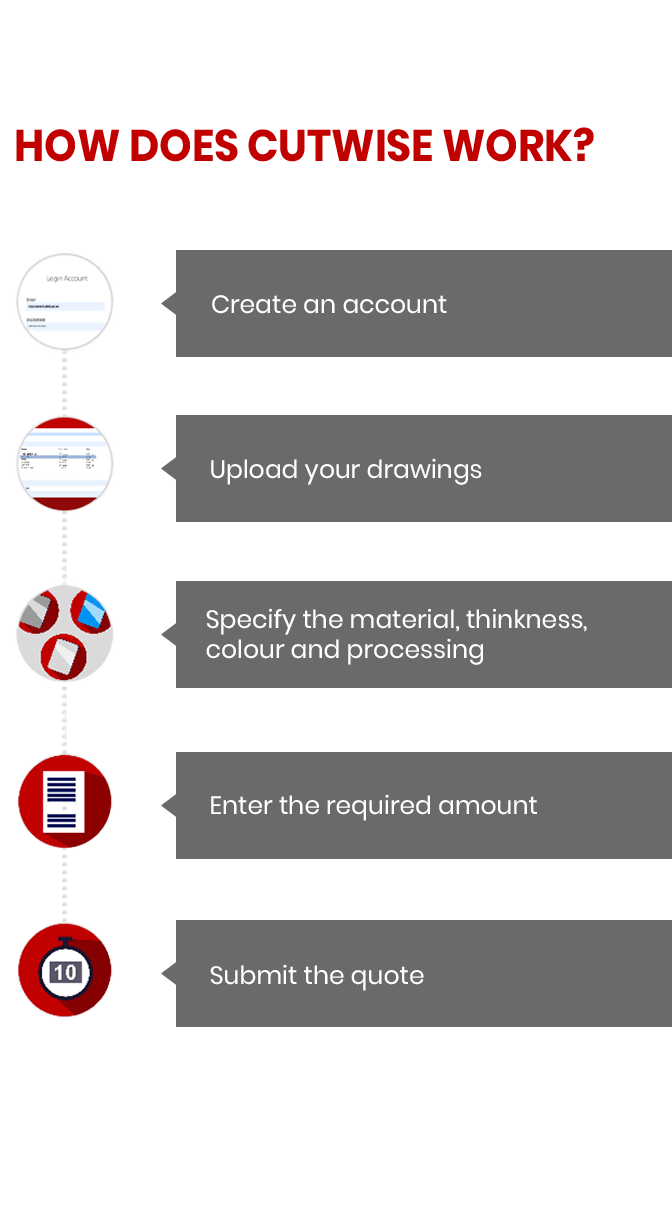

A CUSTOM QUOTE FOR LASER CUT INTERMEDIATE PRODUCTS INSTANTLY

Would you like to receive a custom quote for laser cut intermediate products within 10 seconds?

It’s possible now thanks to CutWise by BMTEC.